Pop-up notes are active on this page - Click any note number to view

| |

|

Industry in Beeston - Telecommunications

For virtually the whole of the 20th Century, Ericssons - and its successors in the telecommunications industry, Plessey and Siemens - were a major employer in Beeston.

When local men or women were asked where they worked, the reply would often be "down at Ericssons". The factory itself prospered, it was considered a good place to work and generations

of Beeston folk made their living there. And, it did more - it gave many of those who worked there a skill set, learned in a well-organised environment which widened their knowledge and

offered them a welfare and social activities framework that they could appreciate and benefit from.

|

The National Telephone Era - In 1901, the National Telephone Company, which then operated telephone services throughout much of the United Kingdom, opened a factory just below the

railway station at Beeston to repair and develop telephone equipment. This original factory, built in 1896, and known as 'Nelson Cycle Works', had been operated by the cycle manufacturer

Humber and Goddard 1. It covered just a small part of a 20 acre site on the south side, and immediately adjacent to, the

Nottingham to Derby Midland Railway line and was the latest example of a manufacturing firm taking advantage of readily available, relatively inexpensive land within reach of Beeston’s

ready workforce. It also offered the opportunities for development which were to be taken full advantage of over the coming decades. National Telephone, which had been formed in 1881 had

had some success but had also faced difficulties in its attempts to set up a nation-wide telephone service with competition from rival firms, a requirement to licence with the Post Office

under the Telegraph Act of 1869 and difficulty in establishing the rights to lines, particularly in urban areas. Its Beeston factory was opened to handle the increased workload faced by the

company's Nottingham factory - which it had opened in 1893. This new location at Beeston employed about 130 people.

The success of the Nottingham factory and later the Beeston factory owed much to the ability and dedication of John William Ullett who was one of the early pioneers of the telecommunications

industry in Britain. The son of a farmer, he was born in Huntingdonshire in 1859. After an education at Merchant Taylors' School in London he went on to study at the School of Telegraphy,

also in London. In 1879 he joined Telephone Company Ltd, which was to open the first public telephone exchange (with eight subscribers) in London in that year. Further exchanges in London and

in various provincial cities followed very shortly afterwards. In the years that followed he carried out pioneering research into aspects of switchboards and telephone circuitry and equipment and

was involved in the development of cabling between London and the north of England. In 1889, after several amalgamations, what had been The Telephone Company was amalgamated with National Telephone

Company. Ullett opened its Nottingham factory in Colwick in 1893, taking full charge of its planning and on-going management. Its further factory at Beeston which, as we have seen, was opened in

1896, was also planned and controlled by him. It was to be a very fortunate combination for both the company and for Beeston 2.

Ericsson Arrives - A large proportion of the telephone equipment that was used and installed by the National was acquired from L M Ericsson & Company in Sweden. Britain and its colonies were clearly a valuable

market for Ericsson but it was very aware that it needed to increase its manufacturing capacity to address this likely opportunity and that a presence in Britain would be a distinct advantage in

securing and servicing these markets 3. In November 1903, National joined with L. M Ericsson & Company, in equal parts, to form

British L M Ericsson Manufacturing Co. Ltd with an office in London 4. National's Beeston factory was transferred to the new company

as part of the deal and the manufacture of telephone apparatus and appliances began on the site.

However, production had only just got under way, with a workforce that was already about 300, when fire struck. In the early morning, just after midnight on 3 December 1903, a fire was discovered by the night watchman

in the wood polishing department The Beeston brigade arrived with its manual engine and hose wagon and immediately called for help from the Nottingham brigade. They fought the fast spreading fire

for several hours but their efforts were limited by inadequate water pressure from the nearby hydrants 5. When, at 9.30am, the fire

was finally out, the damage was seen to be substantial. Work was suspended at the factory while alternative plans could be put together for an immediate rebuild on the site.

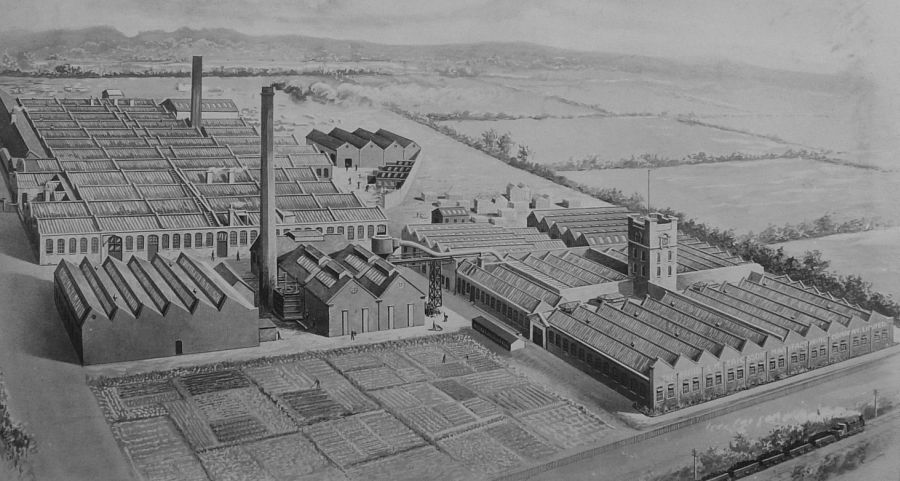

The rebuilt factory building - shown here and always known as 'B Block' - was planned and developed by John William Ullett who had continued in the employment of British L M Ericsson after it had taken over National's Beeston site.

He did a first rate job and, managed by him, it was soon up and running, fully equipped for the production levels that the market was demanding, in an impressive departmentalised environment that was soon setting the standard for efficiency

and for excellence in the provision of employee welfare. In 1905, National was informed that it was the Government's intention to terminate its licence to operate telephones and that the Post Office would be buying out

and taking over its assets in 1912 but, despite this, Ericsson continued to invest in the Beeston site. A boiler room - with a distinctive chimney which remained as a landmark for over 80 years - and a power plant was

The rebuilt factory building - shown here and always known as 'B Block' - was planned and developed by John William Ullett who had continued in the employment of British L M Ericsson after it had taken over National's Beeston site.

He did a first rate job and, managed by him, it was soon up and running, fully equipped for the production levels that the market was demanding, in an impressive departmentalised environment that was soon setting the standard for efficiency

and for excellence in the provision of employee welfare. In 1905, National was informed that it was the Government's intention to terminate its licence to operate telephones and that the Post Office would be buying out

and taking over its assets in 1912 but, despite this, Ericsson continued to invest in the Beeston site. A boiler room - with a distinctive chimney which remained as a landmark for over 80 years - and a power plant was

added and, in 1906 an extensive cabinet shop. Everything it needed was now in place on the site to turn raw materials into finished products, in a self-contained operation and it was soon recognised as a pioneer, setting

examples in efficiency and employee facilities which others would follow.

added and, in 1906 an extensive cabinet shop. Everything it needed was now in place on the site to turn raw materials into finished products, in a self-contained operation and it was soon recognised as a pioneer, setting

examples in efficiency and employee facilities which others would follow.

An article in the 'Electrical Review' dated 3 July 1908 6 was particularly full in its praise of the recently opened factory. The 'old factory building' -

i.e. B Block where much of the manufacture and assembly took place - covered an area of 63,000 square feet, the cabinet factory (C Block), 70,000 square feet and the power station (A Block) a further 7,000 square feet,

making a total of almost 140,000 square feet. The site itself covered 20 acres, leaving plenty of scope for expansion. The extensive and efficient machinery and equipment throughout the factory, all of a very high standard,

both in quantity and quality, with everything on one floor and with electric drive, power and lighting provided throughout. A particular feature of the main factory building was a central covered corridor which opened onto the

Nelson Road frontage (Shown Right) through which all employees could enter and leave and through which components and material could be easily be moved from department to department throughout the day. Already, in these

early days, sports activities had begun to be developed, Teams - beginning with a football team - were active in the company's name and facilities began to be developed on the spare land around the factory.

Clearly the facilities at the factory were now of an order which ensured that it could provide everything that was required by the manufacturing process, but it is some of the detail within the article that catches the

eye. It seems that the problems encountered during the fire a few years earlier had not been forgotten as the site was now protected by sprinklers and fire hydrants throughout. And, the site had its own dedicated water supply

from an 18 inch bore-hole into the gravel strata and a large underground tank which collected rainwater from the roofs. In the cabinet factory - where the final assembly of switchboards also took place - fireproofed internal

walls and fire doors were in place and a water tower provided extra protection. The whole factory was fed with hot air in the winter and by cool air in the summer. All machines were fitted with dust extractors with the shavings

carried through trunking to the power station. Cost control, design and testing facilities were of a very high order.

Of particular note were the provisions for employees welfare with features that were then by no means universal in British factories. There was a canteen which served hot meals and sold some food at cost price. The

lavatories were well appointed and kept clean and orderly and there was an adjoining first-aid room where minor accidents could be treated. All features which would be taken for granted today but gratefully appreciated by the

workforce at that time.

Almost overnight the extended factory became a major employer in Beeston – about 600 in these early years – and, as we will see, the numbers would continue to expand dramatically. The increase in numbers employed naturally led to

a demand for houses in the area. Trafalgar Road and Victory Road - which names continued the 'Nelson Road' theme - were laid out and houses built where previously there had been little more than open fields. Later Birch Avenue and

Grenville Road would be added to provide more homes as employee numbers continued to grow. The Rylands area itself was being transformed.

In 1911, the Swedish parent company, L M Ericsson, and its Directors and their friends, bought out National Telephone's share of British L M Ericsson Manufacturing Co. Ltd and, in the following year, as had been indicated in 1905,

National's licence to operate as a telephone services provider was canceled and its exchanges, networks and subscribers were taken over by the Post Office. This meant that only services in Hull, Portsmouth and Guernsey remained outside

the essentially nationalised telephone system operated by the Post Office. And, Ericsson's British manufacturing arm - now well established in Beeston - was well positioned to supply to it. To finance these changes and the continued

expansion that would be necessary, the company's capital was increased from £100,000 to £200,000 by a public issue of shares and, a little later, by a debenture issue of £100,000. The company, which was now employing about 900, seemed

in an excellent position to benefit from the expansion of the telephone system in the UK that was, it seemed, sure to follow.

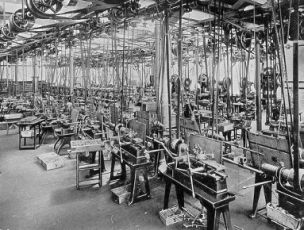

War ! - But, in August 1914, all that was put on hold - in fact it was by no means certain that things would ever return to normal - when war came and changed everything. During the war years,

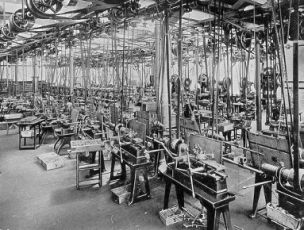

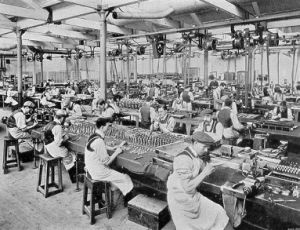

all of industry was tightly controlled by Government agencies and they were directed as to the product they were to produce and limited accordingly as to the raw materials they had available. The image below left shows a machine

shop at the Beeston works, fully engaged in war production in this period.

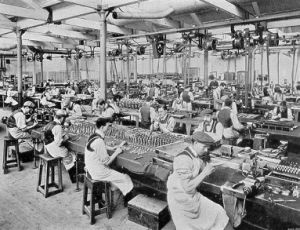

Many young men had enlisted immediately or soon after war was declared and most of those who didn't - some were exempt - were conscripted. This came at a time when the factories and workshops they worked in needed to keep

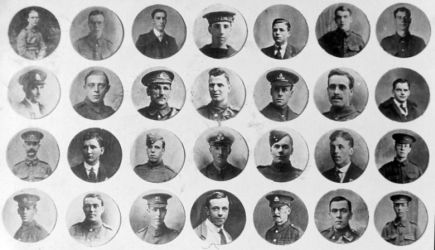

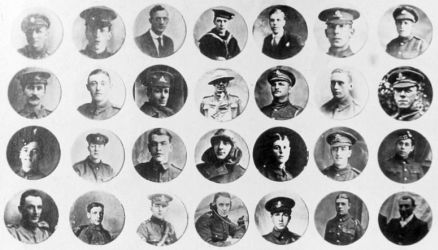

production at full stretch to produce the armaments and equipment to supply the battle fronts. While younger and older men - the image above right shows an Ericsson group, mostly very young men, from this time - played their part in filling

the enormous gap, the largest contribution - and biggest change to the social norms - came with the large-scale employment of women who provided a much larger proportion of those required to work the machinery.

For most factories, the war requirements meant a complete change from the normal product output. At the Ericsson Beeston factory, this was rather less the case - as its telecommunication skills were much in demand for the production of

field communications equipment. However, its workshop machinery was also used to manufacture armaments and specialist tooling and its technical expertise was used to develop new related lines in wireless technologies. For instance, earphones

that it developed were adopted as standard by both the Admiralty and the Air Force.

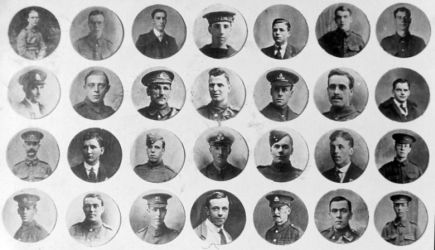

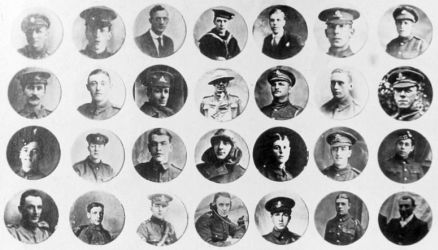

A large part of the male workforce served during the Great War. At Christmas 1918, just after the Armistice had brought fighting to an end, a house magazine within the company showed images of "Some of the B.L.M.E Boys Who Have Joined H.M,

Forces". The three panels which show 84 unnamed portraits of Beeston Ericsson men, are shown above. Sadly, some were killed or injured 7.

Peacetime Again - After the war finished in 1918, men began to return and take up their jobs again - with the 51-hour working weeks now thankfully reduced to 47. Though this meant that many of the women employees returned to their previous

traditional role in the home, a large number of women continued to be employed in manufacturing and administration roles. The company's well developed manufacturing facilities were again producing telephone sets and small exchanges and supplying much

of the Post Office's needs. Already though, the need to move into larger, automated exchanges had been identified and development had commenced accordingly. But the decisions - and resulting demand - in that area were a few years away so, in the meantime,

the company kept its facilities busy by developing a range of crystal sets, valve radios, headphones and loudspeakers as well as specialist telephone equipment for mines and railway use.

In 1918, John William Ullett retired from his position as Works Manager. He had been key to the successful development of the Beeston factory and, indeed, had become recognised as an expert in the development of production facilities and the systems

used to control them. Indeed, during the war years he had been a member of the Advisory Committee that equipped and controlled the Shell Filling Factory at Chilwell which had been so vital to supplying the Western Front

8. His successor as Works Manager was Allan Fergusson Wood who had moved to Beeston originally in 1910 9 to take up a position at Ericssons.

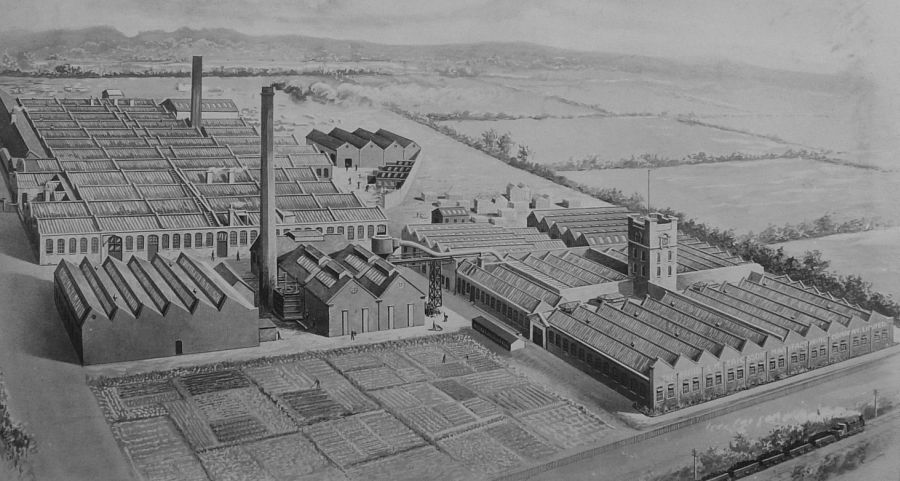

The Factory in 1921

It was in this year, the 20th anniversary of the Beeston telephone works, that the whole factory, now employing 1300 employees, was photographed for posterity The photographs have survived in a presentation album

10 and are now made available here. The aerial view of the factory site, with buildings covering seven acres, is shown above. The land surrounding the factory buildings, available for

future future expansionm is clearly then in use for allotment gardens - presumably for employees - and other areas of otherwise vacant land provided sports grounds for employees.

We have divided the photographs into five sections for convenient access:

Production Departments, Assembly Departments,

Support Departments, Service Departments &

Administration & Management Departments

By the 1920s, the Post Office had adopted the Strowger system as the basis of the automatic telephone exchanges that were needed throughout the United Kingdom for the comprehensive telephone system that it now supported. This

electromechanical system was developed from an original concept by Almon Brown Strowger, an American undertaker, as early as 1888. After developing the idea and the earliest automatic telephone exchanges in the

United States the patent was eventually acquired by Bell Systems and the much-modified concept was adopted throughout much of the world 11. The Post Office first adopted a then state-of-the-art development

of this system called the Director telephone system which allowed for automatic direction of dialed numbers throughout a network of exchanges within large cities and their surrounding areas. Now, with these telephone exchanges being rolled out throughout the

country, 12 a period of sustained growth developed in the industry, of which Ericsson's Beeston became an important part.

In 1926, in order to address these opportunities, the company's share capital was increased, by public subscription, from £200,000 to £500,000 and its name was changed to Ericsson Telephones Ltd. In the following year, the company joined a bulk sale agreement with

the Post Office, with four other manufacturers, to supply automatic exchange equipment. This began a period of growth at the site which included new facilities and an increased workforce which more than doubled over the next ten years to reach 4000 by 1939. In 1933, the

company bought the adjacent cricket ground, next to the railway station to maintain sporting provision for this increasing workforce at a time when the existing site was under pressure from new building. It was a period when the site was ably managed by

the Swedish-born engineer John Engblom 13 who held the position of General Manager and Chief Engineer there for about 25 years from 1925. He had a reputation as a strict but fair employer and an excellent

manager who insisted on high standards of cleanliness throughout the site. He was an active Rotarian and took an interest in the local community, especially the local musical world.

A Remarkable Visitor - By the early 1930s, the Indian activist, Mahatma Gandhi was completely dedicated to his campaign for Indian independence from British rule. That was the background when, on 17th October 1931, during a visit to Britain as a delegate to an India Round Table Conference in

London, he arrived in Nottingham to visit his nephew, Mr J V Joshi who was, at that time, a student at Nottingham University College and, as it so happened, was undergoing work experience at the Ericssons Beeston Factory. When it was found that Gandhi intended to lunch with his nephew at his

lodging at 13 Linden Grove, Beeston, John Engblom, the Works Manager at the Ericsson factory was determined to extend the visit to include a tour of the factory.

Gandhi arrived at Nottingham station, dressed in his characteristic shawl, loin cloth and sandals and was met by a small

crowd of people and without undue demonstration. Mr Engblom was amongst those to meet him and they walked together to Gandhi's car engaged in conversation. Against original intentions and despite tight time constraints, he agreed to make a flying visit to the Ericsson works where he was welcomed by

Mr Engblom who invited him to sign the visitors book and was able to be shown something of the works in the short time available.

Upon his arrival at Linden Grove, where he took a meal at his nephew's lodgings, he was greeted by a large group of school children who cheered the Indian visitor.

One schoolgirl took a bouquet to the house with the message "The whole world is watching with admiration your unselfish efforts for the people of India".

Mr Gandhi finished his visit with a visit to Nottingham University where he was received by staff and students - including a few Indian

students - in a crowded Great Hall. After addressing the audience he left For Birmingham to continue his mission 14.

It had been a remarkable few hours for Nottingham and for Beeston in particular.

|

Not Just Telephones - Although the manufacture and supply of automatic exchanges was the main focus during this period, the company continued to innovate, producing a range of products, mostly derived from its core technologies in telephony. Sometimes too, it acquired the rights to promising concepts. In

1930 for instance, it bought out Automatic Totalisators Ltd which held the patent rights to the automatic totalisator which were then being installed at race courses - and later dog racing tracks - widely throughout the country, following the Racecourse Betting Act of 1928.

Following the acquisition, Ericsson closed down its Ealing factory - which it had previously supplied with parts - and moved production to Beeston. The company's recognition that the units needed to be portable so they could follow the various racing events was a major factor

in its success in this market and, as it turned out, the venture was to make a significant contribution to profits throughout the 1930s 15.

Not Just Telephones - Although the manufacture and supply of automatic exchanges was the main focus during this period, the company continued to innovate, producing a range of products, mostly derived from its core technologies in telephony. Sometimes too, it acquired the rights to promising concepts. In

1930 for instance, it bought out Automatic Totalisators Ltd which held the patent rights to the automatic totalisator which were then being installed at race courses - and later dog racing tracks - widely throughout the country, following the Racecourse Betting Act of 1928.

Following the acquisition, Ericsson closed down its Ealing factory - which it had previously supplied with parts - and moved production to Beeston. The company's recognition that the units needed to be portable so they could follow the various racing events was a major factor

in its success in this market and, as it turned out, the venture was to make a significant contribution to profits throughout the 1930s 15.

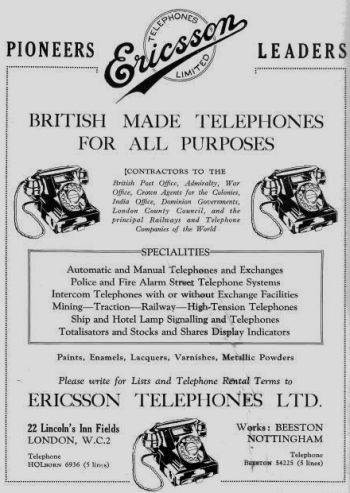

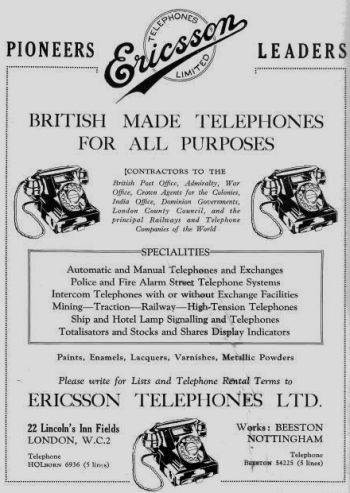

A newspaper report of the 1937 Annual General Meeting 16 painted a glowing picture of the Beeston site, describing it as a model factory which was doing all the right things, with "exactitude" the key to its success. There

were other factors too - amongst those mentioned were the company's ability and enterprise, its willingness to spend on machinery and building, its sound management, an ability to exploit opportunities outside its core business, well equipped research units and a human and personal touch with

employees, even with increasing staff levels. While the core business remained firmly with telecommunications - where the writer was particularly impressed by the "robotic" cleverness of the automatic telephone exchanges - the company had used its expertise and facilities to recognise

and exploit opportunities as they had emerged, in areas such as the production of metal parts for the motor industry, price displays for stock exchanges and cellulose enamels and varnishes. An advertisement from this era (Shown Right) gives an indication of the

company's impressive range of products and markets. The statistics were remarkable - by then, 80,000 different parts were being made on site, backed by a library of 420,000 blueprints and involving 4.4 million strokes by the presses each week. The coil winding shop was the most modern

in the country and turned out 9,000 - 10,000 relay coils every week. The results of this successful formula had shown themselves in the financial figures. In the ten years up to 1937, turnover had increased threefold, profits, at £140.6k, were five times greater than at the start of the

ten years, dividends had risen accordingly and the balance sheet was extremely strong. Even then, the company was continuing to develop the Beeston site - the latest development earmarked for a venture to manufacture a red lead under licence, designed to capture the British market from

foreign competitors. Beeston Ericssons, it seems, was doing everything right.

War Again - The arrival the war years in 1939 was, of course, destined to put much of this on hold - but the resources and expertise it had built up were priceless to the vital war effort. Once again, many of its male workers were drafted into the armed forces and women carried out many of the

jobs in their absence, either voluntarily or, from 1941, by conscription. Many men, not eligible for service in the armed service, were directed to essential work. There was an immediate problem with the continued involvement by Swedish Ericsson as there was great concern that

Sweden, which had taken a neutral stance in the war but had tolerated the passage of enemy troops, remained vulnerable to invasion. To guard against threats of seizure of the company under the Trading With the Enemy Act of 1939, the Swedish company

reduced its shareholding to less than 49% and the Swedish Directors resigned from the Board. The General Manager, John Engblom, returned to his native Sweden in May 1940 rather than face possible internment 17.

Now under war conditions, the factory was directed as to what it produced with its total output focused entirely on the needs of the war effort. A good part of this was. naturally, using its skills as a supplier of telephony by replacing equipment damaged by bombing and supplying specialist

telephony for the network of war stations. It was also able to use its valuable technical knowledge, skills and equipment to supply specialist radio and radar equipment as well as bomb sights and releases to the RAF. It also supplied specialist paint and varnishes and large quantities of

aluminium powder for use in the manufacturing of bombs. The research department and the skilled engineering departments provided rare skills, often in great secrecy. One example of this only became known after the war, that Hiram Crossland Firth, the Tool Room foreman was asked to produce

bomb 'hooks', probably used to hold and release bombs during raids over Germany. He is said to have worked alone in secret, sometimes eating and sleeping in the workshop 18. The factory, although heavily camouflaged, had

upwards of 5,500 workers, working in shifts around the clock during this time, and was obviously a prime target for the enemy planes. Three large concrete air raid shelters were provided for the workforce 19 and the factory

had its own fire team (Click the image to see more) and dedicated Home Guard cover. Thankfully, despite a number of air-raids in the area, the factory survived to carry out its vital work.

Now under war conditions, the factory was directed as to what it produced with its total output focused entirely on the needs of the war effort. A good part of this was. naturally, using its skills as a supplier of telephony by replacing equipment damaged by bombing and supplying specialist

telephony for the network of war stations. It was also able to use its valuable technical knowledge, skills and equipment to supply specialist radio and radar equipment as well as bomb sights and releases to the RAF. It also supplied specialist paint and varnishes and large quantities of

aluminium powder for use in the manufacturing of bombs. The research department and the skilled engineering departments provided rare skills, often in great secrecy. One example of this only became known after the war, that Hiram Crossland Firth, the Tool Room foreman was asked to produce

bomb 'hooks', probably used to hold and release bombs during raids over Germany. He is said to have worked alone in secret, sometimes eating and sleeping in the workshop 18. The factory, although heavily camouflaged, had

upwards of 5,500 workers, working in shifts around the clock during this time, and was obviously a prime target for the enemy planes. Three large concrete air raid shelters were provided for the workforce 19 and the factory

had its own fire team (Click the image to see more) and dedicated Home Guard cover. Thankfully, despite a number of air-raids in the area, the factory survived to carry out its vital work.

Peacetime Challanges - The post-war world brought its own chsllenges. Whilst the demand for the firm's products were excellent it faced difficulties in the transition when labour shortages resulted from delays in the availability of suitable men after many women left to pick up their pre-war lives, a

problem that was reflected through the supply-chain leading to material shortages 20. And. just when this problem was beginning to me faced down, the winter of 1947 presented new problems when weeks of heavy snow, freezing

temperatures and fuel shortages threatened production. The floods that followed presented a further problem but, although the Rylands and lower parts of Beeston, including the factory site, were flooded, the determined workforce was ferried to work in lorries and production continued. This was a

difficult time but the company's strong market position, dedicated core workforce, excellent management and strong balance sheet saw it through, into a further period of growth in employee numbers, innovation and market success.

After John Engblom's departure, the site had been managed, throughout the challenging war years, by Bernard Oglie Anson who, after an early career as a Post Office Telephones engineering manager had moved to the Home Office as an Assistant Secretary just prior to the war before taking

charge of the critical war work then underway at the Beeston factory 21. Following his death in August 1946, the company appointed Air Commodore William Charles Cooper - seen right 22

- to the position of Works Manager in October 1946. He went on to quickly establish himself in that position and became a popular figure amongst the employees and the wider Beeston community, He had had a glittering career with the RAF. Born in 1906, he became a aircraft apprentice at RAF

Flowerdown, went on to Cranwell and Cambridge University before rising quickly through the ranks in the RAF. In the war years, he was head of the Application Division of the Royal Aircraft Establishment and then a Director of Communications with the Ministry of Aircraft Production. He was

to receive the Order of the British Empire, for this work, in November 1947 23. His arrival to take charge in Beeston had coincided with the problems of the 1946/47 winter. His decisive action, keeping production going,

reducing short-time working and avoiding lay-offs 24 was obviously popular and he was to go on the take more popular moves by introducing a 44-hour week and improving the social and sporting lives for factory employees and

their families. In January 1947, in the midst of he difficulties of that winter, he was even able to announce the acquisition of a new 10-acre sports field on Trent Vale Road 25. He was to become a well-known figure in the

wider community too - amongst many positions he accepted, he was the first Commodore of Beeston Sailing Club, was an enthusiastic supporter of the Beeston Carnival, scouting and other youth activities and much more.

After John Engblom's departure, the site had been managed, throughout the challenging war years, by Bernard Oglie Anson who, after an early career as a Post Office Telephones engineering manager had moved to the Home Office as an Assistant Secretary just prior to the war before taking

charge of the critical war work then underway at the Beeston factory 21. Following his death in August 1946, the company appointed Air Commodore William Charles Cooper - seen right 22

- to the position of Works Manager in October 1946. He went on to quickly establish himself in that position and became a popular figure amongst the employees and the wider Beeston community, He had had a glittering career with the RAF. Born in 1906, he became a aircraft apprentice at RAF

Flowerdown, went on to Cranwell and Cambridge University before rising quickly through the ranks in the RAF. In the war years, he was head of the Application Division of the Royal Aircraft Establishment and then a Director of Communications with the Ministry of Aircraft Production. He was

to receive the Order of the British Empire, for this work, in November 1947 23. His arrival to take charge in Beeston had coincided with the problems of the 1946/47 winter. His decisive action, keeping production going,

reducing short-time working and avoiding lay-offs 24 was obviously popular and he was to go on the take more popular moves by introducing a 44-hour week and improving the social and sporting lives for factory employees and

their families. In January 1947, in the midst of he difficulties of that winter, he was even able to announce the acquisition of a new 10-acre sports field on Trent Vale Road 25. He was to become a well-known figure in the

wider community too - amongst many positions he accepted, he was the first Commodore of Beeston Sailing Club, was an enthusiastic supporter of the Beeston Carnival, scouting and other youth activities and much more.

Apprenticeships and training had always been a feature at the Beeston factory but now this became a major focus and of management and a training school was established alongside formal craft and graduate training schemes (Click to see

the 1946 graduate input). These were particularly important initiatives at a time when the original senior staff were coming up to retirement and, particularly so, when new technologies were emerging that required in-house expertise to be developed. Much of this new expertise was, in

the field of valve design - notably cold cathode valves and the 'Dekatron' counting tube 26 which became a feature of computers and other counting products during the 1950s and 60s, before transistors became practical and

reliable alternatives.

The Payroll Robbery - in 1956, Ericssons in Beeston was involved in a major incident which was featured by the national press and by provincial newspapers throughout the length and breadth of the country. With about 6000 employees it processed a substantial

weekly payroll 27 and took what it considered to be every precaution when collecting the necessary cash - which then was the norm for wage-earners - from the bank in Beeston. The transfer was made by car

by two of the firm's senior cashiers - one of them armed - accompanied by a driver and the firm's security officer, with the car taking a different route each week - though, there was a flaw with this latter point as, in practice, the car tended to always travel along

Trafalgar Road as it approached the factory in Beeston Rylands.

So it was, that the transfer was underway on Friday 7th September 1956. As usual, four men were in the car - cashiers Joseph Hemmings and Archibald Allison. security officer Jack Tideswell and driver

Jack Eastham 28. Having picked up over £38,000 in cash 29, they were heading back to the factory to pay it out to the workforce in the normal

way when, as the car entered Trafalgar Road, a well-planned attack was played out. Suddenly, a Land Rover car containing three men rammed the Ericsson car causing it to stop. The man from the Land Rover were then joined by two others from another waiting car and together they attacked the

Ericsson car with hammers and a crowbar, smashing the windows and hitting the driver whose attempts to drive on were thwarted by the intensity of the attack, the damage to the car and, very soon, the removal of the ignition key by the attackers. The swiftness of the attack

also prevented the use of the pistol in defence and, in a very short time three Gladstone bags containing £37,793 in notes were snatched from the rear of the car - about £800 in coin was left behind - and the attackers sped off in their second car which had been standing

ready with a driver, with its engine running, ready to go 30.

The level crossing at the station, then a notorious potential obstacle 31, may

well have been their undoing but, either by luck or excellent planning, they were able to speed across the open level crossing and then turn towards Nottingham. Road blocks were hastily set up in all directions and the getaway car was later found abandoned in West Bridgford. It was

later found that the robbers had spent the next day or so in a pre-arranged location in Nottingham where they shared out the money and waited until the chase had quietened down.

In the event, it wasn't long before arrests were made, starting with Dennis George Henry Barry,

a 29-year-old clerk from Brixton, London who was, later to plead guilty to being involved in the attack. Francis Victor Hornett, aged 36, a shopkeeper from Banstead in Surrey was arrested soon afterwards but strenuously denied any involvement. Four others were accused of being

accessories by harbouring those involved. Four others, who had been directly involved, were never found.

At Birmingham Assizes on 13 December 1956, Hornett and Barry were found guilty and sentenced to seven year's imprisonment for their part in the robbery. Two men and a

woman from the London area were found guilty of harbouring Barry after the robbery and received lesser sentences 32. Almost all the cash, it seems, was never recovered

|

During the 1950s, the development of the Beeston site continued, occupying much of the vacant land - particularly alongside the line of the railway - and a large canteen complex was added to cater for the increased number of employees - by then upwards of 6,000. These changes provided space for specialist areas

for departments giving increasing attention to electronic products and solutions including the development of all-electronic exchanges. In 1958, the need to fully embrace the transistor was addressed by the company's entry into a joint venture with Automatic Telephone & Electic Co and English Electric to be

called Associated Transistors which was to develop and manufacture these in quantity. Now, as the 1950s came to an end, it was clear that the market was changing with the dramatic developments that were occurring in technology. As we will see, these changes would take place alongside big changes to

the company itself.

The Plessey Years - in 1961, Ericssons Telephones Limited, together with Automatic Telephone & Electric (AT&E) which was based in Liverpool, where acquired by The Plessey Company and merged into its Telecommunications Division to become Britain's largest manufacturer of telecommunications

equipment - alongside its Radar and Marine Divisions - of a size that was much better placed to respond to the challenges that the developing electronic and emerging digital technologies had brought to the sector. The Beeston site was to become its Private Communications and Data Systems Division and continued to develop,

both in terms of facilities and employees, to respond to the challenges and opportunities that were available in that sector.

All three of the now merged companies - along with the General Post Office, Siemens, General Electric (GEC) and Standard Telephone & Cables - had been part of the Joint Electronic Research Committee which had been formed in 1956 to decide a way forward amongst differing ideas in the industry for the

next generation of telephone switching technology which promised the convenience and cost-savings of automatic long-distance connections as well as the efficiency of electronic exchanges to replace the existing electro-mechanical Strowger-based telephone exchanges. In the early years of this transition

period, each of the participants was permitted to develop and implement solutions based on its own ideas and specialisations with the committee providing overall oversight. What emerged, given that digital systems were not yet practicable, were systems (known as TXE) based on electronic Control circuitry driving reed

relays 33. The Plessey merger would have the effect of rationalising the technical approach of three of the participants within this generally agreed approach to the General Post Office's telecommunications needs.

The opportunities were clearly attractive but the challenges - both technical and commercial - were considerable. The technical expertise at the Beeston site was already exceptional and now needed to be maintained, with increasing numbers included in the regular graduates intakes and through new training facilities.

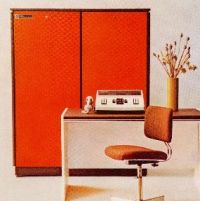

Improved stores, sales-office facilities and a modern seven-storey office bock (E-block - shown here) were added to the site to support the anticipated market opportunities. Over the next decade, employee numbers grew steadily, to reach a peak of 8000 in the early 1970s. Out of hours activities for these

employees were excellent. The Company Sports Field on Trent Road now hosted a range of well-organised and well-achieving team sports, including football, cricket and hockey, as well as an annual Sports Day that attracted employees, their families as well as the general public. The very popular Sports & Social Club

also added to the community feeling for those that worked at the Beeston site and their families.

The opportunities were clearly attractive but the challenges - both technical and commercial - were considerable. The technical expertise at the Beeston site was already exceptional and now needed to be maintained, with increasing numbers included in the regular graduates intakes and through new training facilities.

Improved stores, sales-office facilities and a modern seven-storey office bock (E-block - shown here) were added to the site to support the anticipated market opportunities. Over the next decade, employee numbers grew steadily, to reach a peak of 8000 in the early 1970s. Out of hours activities for these

employees were excellent. The Company Sports Field on Trent Road now hosted a range of well-organised and well-achieving team sports, including football, cricket and hockey, as well as an annual Sports Day that attracted employees, their families as well as the general public. The very popular Sports & Social Club

also added to the community feeling for those that worked at the Beeston site and their families.

The first of the Plessey TXE exchanges - known as TXE2 - was installed at Ambergate, Derbyshire, a relatively small exchange, conveniently close to the Beeston site, which opened on 15 December 1966. Eventually, between 2000 and 3000 TXE2 systems, shared between Plessey and the other participants in the programme were eventually deployed.

However, all were to be replaced when digital technologies arrived, the last being closed in June 1995 34.

The Plessey TXE2 design had been based on its Pentex system and this continued to evolve for its export market and became a major component of the Company's success during the 1970s, during which Pentex was exported to over 30 countries. In 1978, largely as a result, Plessey was awarded the Queen's Award for Exports.

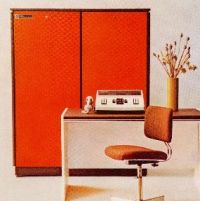

But, digital technology was clearly the future and Plessey was to address its opportunities comprehensively when it opened the Abbeyfield Road Digital Technology Centre in Lenton, Nottingham in 1976. It was there that what was reputed to be the first digital switch in the UK, the PDX private digital exchange (Shown Right)

was designed and built. A series of ground breaking digital products followed and were launched into the buoyant market following the privatisation of British Telecom in 1984 35. About half a million such units were produced in these years which led to the addition

of extra production facilities at the Beeston site to meet this high demand although the improved efficiency of the new facilities and less labour-intensive nature of the work began to have its effect on employee numbers. From the peak of 8000 in the early 1970s, the number employed had dropped to about 6000 ten years later.

But, digital technology was clearly the future and Plessey was to address its opportunities comprehensively when it opened the Abbeyfield Road Digital Technology Centre in Lenton, Nottingham in 1976. It was there that what was reputed to be the first digital switch in the UK, the PDX private digital exchange (Shown Right)

was designed and built. A series of ground breaking digital products followed and were launched into the buoyant market following the privatisation of British Telecom in 1984 35. About half a million such units were produced in these years which led to the addition

of extra production facilities at the Beeston site to meet this high demand although the improved efficiency of the new facilities and less labour-intensive nature of the work began to have its effect on employee numbers. From the peak of 8000 in the early 1970s, the number employed had dropped to about 6000 ten years later.

With this trend set to continue, management began the process of development and diversification on the site. During this process, some redundant buildings were demolished, notably three concrete, and by then somewhat iconic, structures which had provided shelter for employees during air-raids in the second world war. A new

access road to provide improved access the rear of the site was built and, in partnership with the local council, a Business Park was introduced.

GPT and Siemens - in 1988 GEC entered into a joint venture with Plessey but this became a short-lived arrangement when, in 1991, Siemens and GEC took over Plessey and continued operation at the Beeston site under the name of GPT. Sadly, by now, strong competition from the Far East threatened the viability of its

telecommunications products and employee numbers had dropped to 3000. This steady decline was to continue and rationisation of the site facilities proceeded alongside the reduction in numbers employed. In 1998, Siemens took over full ownership of the site with a new name - Siemens Communications Limited ('SCL')

36. Faced with a highly experienced workforce but a telecommunications market that was by now saturated, Siemens sought to diversify by marketing its top-rank manufacturing and design expertise that the site possessed. By 2000, there were still about 2000

employees on site, working in these and other spin-off markets, winning both new business and many industry awards. Sadly, after about ten years, in 2008, with the workforce down to just 300, Siemens closed the Beeston factory, with a few of those who were left offered jobs at the company's Ansty site, near Coventry.

For the 107 years Ericssons and its predecessors and successors had been present in Beeston, it had set high standards for its working methods, produced ground breaking products and provided generations of local people with employment and skills as well as leisure activities. It had served Beeston well.

But it wasn't all bad news - happily, the Business Park that Plessey had begun to develop in the 1980s and which was further developed by its successors was acquired by the HSBC Group following the closure and provided a base for management buyouts of parts of the residual Siemens operation and for other major hi-tech companies.

It's an excellent start which hopefully heralds an excellent future for this important Beeston site.

Notes

Return to Top of This Page

© David Hallam - 2018

|

|

The rebuilt factory building - shown here and always known as 'B Block' - was planned and developed by John William Ullett who had continued in the employment of British L M Ericsson after it had taken over National's Beeston site.

He did a first rate job and, managed by him, it was soon up and running, fully equipped for the production levels that the market was demanding, in an impressive departmentalised environment that was soon setting the standard for efficiency

and for excellence in the provision of employee welfare. In 1905, National was informed that it was the Government's intention to terminate its licence to operate telephones and that the Post Office would be buying out

and taking over its assets in 1912 but, despite this, Ericsson continued to invest in the Beeston site. A boiler room - with a distinctive chimney which remained as a landmark for over 80 years - and a power plant was

The rebuilt factory building - shown here and always known as 'B Block' - was planned and developed by John William Ullett who had continued in the employment of British L M Ericsson after it had taken over National's Beeston site.

He did a first rate job and, managed by him, it was soon up and running, fully equipped for the production levels that the market was demanding, in an impressive departmentalised environment that was soon setting the standard for efficiency

and for excellence in the provision of employee welfare. In 1905, National was informed that it was the Government's intention to terminate its licence to operate telephones and that the Post Office would be buying out

and taking over its assets in 1912 but, despite this, Ericsson continued to invest in the Beeston site. A boiler room - with a distinctive chimney which remained as a landmark for over 80 years - and a power plant was

added and, in 1906 an extensive cabinet shop. Everything it needed was now in place on the site to turn raw materials into finished products, in a self-contained operation and it was soon recognised as a pioneer, setting

examples in efficiency and employee facilities which others would follow.

added and, in 1906 an extensive cabinet shop. Everything it needed was now in place on the site to turn raw materials into finished products, in a self-contained operation and it was soon recognised as a pioneer, setting

examples in efficiency and employee facilities which others would follow. Not Just Telephones - Although the manufacture and supply of automatic exchanges was the main focus during this period, the company continued to innovate, producing a range of products, mostly derived from its core technologies in telephony. Sometimes too, it acquired the rights to promising concepts. In

1930 for instance, it bought out Automatic Totalisators Ltd which held the patent rights to the automatic totalisator which were then being installed at race courses - and later dog racing tracks - widely throughout the country, following the Racecourse Betting Act of 1928.

Following the acquisition, Ericsson closed down its Ealing factory - which it had previously supplied with parts - and moved production to Beeston. The company's recognition that the units needed to be portable so they could follow the various racing events was a major factor

in its success in this market and, as it turned out, the venture was to make a significant contribution to profits throughout the 1930s

Not Just Telephones - Although the manufacture and supply of automatic exchanges was the main focus during this period, the company continued to innovate, producing a range of products, mostly derived from its core technologies in telephony. Sometimes too, it acquired the rights to promising concepts. In

1930 for instance, it bought out Automatic Totalisators Ltd which held the patent rights to the automatic totalisator which were then being installed at race courses - and later dog racing tracks - widely throughout the country, following the Racecourse Betting Act of 1928.

Following the acquisition, Ericsson closed down its Ealing factory - which it had previously supplied with parts - and moved production to Beeston. The company's recognition that the units needed to be portable so they could follow the various racing events was a major factor

in its success in this market and, as it turned out, the venture was to make a significant contribution to profits throughout the 1930s

After John Engblom's departure, the site had been managed, throughout the challenging war years, by Bernard Oglie Anson who, after an early career as a Post Office Telephones engineering manager had moved to the Home Office as an Assistant Secretary just prior to the war before taking

charge of the critical war work then underway at the Beeston factory

After John Engblom's departure, the site had been managed, throughout the challenging war years, by Bernard Oglie Anson who, after an early career as a Post Office Telephones engineering manager had moved to the Home Office as an Assistant Secretary just prior to the war before taking

charge of the critical war work then underway at the Beeston factory  The opportunities were clearly attractive but the challenges - both technical and commercial - were considerable. The technical expertise at the Beeston site was already exceptional and now needed to be maintained, with increasing numbers included in the regular graduates intakes and through new training facilities.

Improved stores, sales-office facilities and a modern seven-storey office bock (E-block - shown here) were added to the site to support the anticipated market opportunities. Over the next decade, employee numbers grew steadily, to reach a peak of 8000 in the early 1970s. Out of hours activities for these

employees were excellent. The Company Sports Field on Trent Road now hosted a range of well-organised and well-achieving team sports, including football, cricket and hockey, as well as an annual Sports Day that attracted employees, their families as well as the general public. The very popular Sports & Social Club

also added to the community feeling for those that worked at the Beeston site and their families.

The opportunities were clearly attractive but the challenges - both technical and commercial - were considerable. The technical expertise at the Beeston site was already exceptional and now needed to be maintained, with increasing numbers included in the regular graduates intakes and through new training facilities.

Improved stores, sales-office facilities and a modern seven-storey office bock (E-block - shown here) were added to the site to support the anticipated market opportunities. Over the next decade, employee numbers grew steadily, to reach a peak of 8000 in the early 1970s. Out of hours activities for these

employees were excellent. The Company Sports Field on Trent Road now hosted a range of well-organised and well-achieving team sports, including football, cricket and hockey, as well as an annual Sports Day that attracted employees, their families as well as the general public. The very popular Sports & Social Club

also added to the community feeling for those that worked at the Beeston site and their families. But, digital technology was clearly the future and Plessey was to address its opportunities comprehensively when it opened the Abbeyfield Road Digital Technology Centre in Lenton, Nottingham in 1976. It was there that what was reputed to be the first digital switch in the UK, the PDX private digital exchange (Shown Right)

was designed and built. A series of ground breaking digital products followed and were launched into the buoyant market following the privatisation of British Telecom in 1984

But, digital technology was clearly the future and Plessey was to address its opportunities comprehensively when it opened the Abbeyfield Road Digital Technology Centre in Lenton, Nottingham in 1976. It was there that what was reputed to be the first digital switch in the UK, the PDX private digital exchange (Shown Right)

was designed and built. A series of ground breaking digital products followed and were launched into the buoyant market following the privatisation of British Telecom in 1984