Arthur Pollard, the Anglo Scotian Mills & Prosperity -

John Pollardís will set up a trust to manage the factory and to provide for his wife Eliza, who continued to live at Cromwell House. The firm then

operated under the name of "John Pollard Executors" until Eliza died in 1922. The trustees were Arthur Pollard, Samuel Weston1 a

lace yarn agent from Nottingham and Arthur Meakin the factory draughtsman. Arthur Pollardís agreement, for taking half of the profits, was renewed by the

trustees and at the age of 40 he was in effective charge of the factory. The period that followed, until the outbreak of World War I, saw the factory

Arthur Pollard, the Anglo Scotian Mills & Prosperity -

John Pollardís will set up a trust to manage the factory and to provide for his wife Eliza, who continued to live at Cromwell House. The firm then

operated under the name of "John Pollard Executors" until Eliza died in 1922. The trustees were Arthur Pollard, Samuel Weston1 a

lace yarn agent from Nottingham and Arthur Meakin the factory draughtsman. Arthur Pollardís agreement, for taking half of the profits, was renewed by the

trustees and at the age of 40 he was in effective charge of the factory. The period that followed, until the outbreak of World War I, saw the factory

prosper. The clock and bell, with its ornamental belfry, were moved around this time from the closed Silk Mill on High Road2. The belfry,

perched rather incongruously on the Swiss Mills roof, could be seen as a statement, a symbol of prosperity. In 1905-6, for example, sales of lace brought

in £37,6003 and profits of £6565. A new engine house was built in 1906 and three new lace machines arrived in that year. Also in 1906,

single story buildings, Earls Court and the Palace4, were erected along Villa Street, and most of the Pollardsí machines were moved there,separate

from those of the tenants. The date and initial "P" on the new engine house5 are shown left.

prosper. The clock and bell, with its ornamental belfry, were moved around this time from the closed Silk Mill on High Road2. The belfry,

perched rather incongruously on the Swiss Mills roof, could be seen as a statement, a symbol of prosperity. In 1905-6, for example, sales of lace brought

in £37,6003 and profits of £6565. A new engine house was built in 1906 and three new lace machines arrived in that year. Also in 1906,

single story buildings, Earls Court and the Palace4, were erected along Villa Street, and most of the Pollardsí machines were moved there,separate

from those of the tenants. The date and initial "P" on the new engine house5 are shown left.

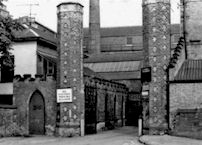

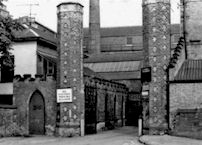

A major development was the purchase of the Anglo Scotian Mills (map on previous page) in 1909. The first lace factory on this site was that of William Felkin,

author of a history of Nottingham lace, but the "Anglo", as we know it, was built by Frank Wilkinson after the fire there in 18926. He made

a fortune from lace curtains, revolutionising marketing methods. The Gothic style frontage is well known and the exotic Anglo Scotian entrance on Villa Street

(shown below right) was part of our childhood landscape.7

Frank Wilkinson died in 1897, aged only 51, and without his leadership his business soon failed. The liquidators spent a considerable amount of money

to make the complex saleable and a new steam engine by Tangye8 was added to the existing Reader engine9. There was also a stationary steam fire

engine, not surprising in view of the fires in the Wilkinson period. In spite of the improvements, this large complex, covering 8120 square yards sold

for the relatively small sum of £8,500. The purchaser was Arthur Pollard, who now owned both the lace factories in the Villa Street area.

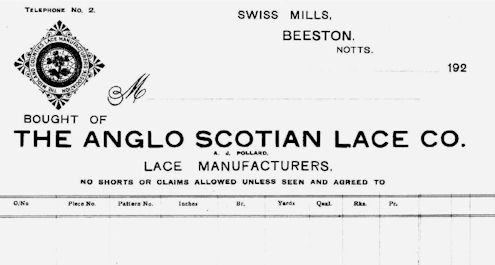

The Anglo was sold with established tenants, lace curtain makers and lace makers, and most continued under the new ownership (Appendix 4). A new boiler

was added, lit by John and Walter10, and a wing built at the Poplars (north) side of the factory in 1911. Like Swiss Mills, the Anglo became a

mixture of rented standings and the Pollardsí own machines although never as many of the latter as at Swiss Mills. The Anglo was run as a separate business,

because Swiss Mills was still in the hands of trustees. The firms were administered from the same (Swiss Mills) office, with, inevitably, occasional confusion

in the books11.

Although the Anglo had a new steam engine just before the 1909 sale, steam was soon replaced by electricity. There is no direct information on the timing

of the change, but entries in the Day Book, suggests that electricity was first used to run machines in 1912. In that year electric motors and Vickersí

generators, presumably powered by the steam engines, were bought for the Anglo (some time around 1920, mains electricy arrived12).

Arthur Pollard was a highly skilled lace technician, recognised as such in the trade. At his death in 1953, A.E. Spowage of Spowage Humphreys and Wyer,

the noted machine builders, said that Arthur Pollard was generally regarded in Nottingham as the most gifted lace man of his time13. He was also a generous

man and we have on several occasions been told by elderly Beestonians of his acts of kindness in difficult times. He did not have the forceful nature of his

father, but this was perhaps less important for an established business. The Pollard lace business was at its peak just prior to the first World War; in the

two factories they had some 55 to 60 machines and there were many tenants with machines of their own.

In 1913, Arthurís son John, like his father before him, went to school in Calais, to learn the language and make contacts in the trade. His father took

him across the Channel and a postcard home from Arthur to his mother at Cromwell House shows that he did not miss the chance to look at the fashions.

| Postcard from Arthur Pollard in Calais to his mother, in 1913 |

| My dear Mar, we arrived quite safe, it was rather rough and very wet crossing, the weather is very fine and hot here, John

is looking very well, there are quite a lot of Nottm manfrs here, there was a great deal of lace worn but not much for Nottm, all silk flounces very

wide, the dresses are very much wider & a good many of them kilted, home Saturday evening love from both - Arthur |

Our fatherís own postcards show that he was unhappy away from home; he must have been one of very few people pleased at the outbreak of World War I, which

saw him start work in Beeston rather than in France.

1 From whose firm the Pollards bought yarn into the 1950s.

2 The clock was made by Bosworth of Nottingham c1842; the clock face was of blue slate, 4ft diameter, and the weight dropped the length of

the 4 storey factory in a week. Information from John Pollard, in conversation with Sheila Mason. The author remembers, as a very small boy, climbing

the stairs with the help of his father to wind the clock. Taylors of Loughborough cast the bell; when on the Silk Mill it was used to call children,

working in the factories, to school for their half day of education. (Judith Church, Beeston Local History Society Newsletter, Christmas 1984).

3 Trading Accounts 1905-6, family papers. The main expenditure was for yarn, "Cotton etc. £13,872".

4 Named the Crystal Palace; perhaps a joke by the workers as it was a dingy place when we were young. However it had roof lights and may

have seemed a little more like a glass palace when new.

5 Rescued after the fire and demolition in 1984.

6 For the life of Frank Wilkinson, see S.M. p.257-8 and Chapman, S. (2005) The history of Beeston lace, C.P. Walker, Beeston, produced

to mark the conversion of the Anglo Scotian Mills to appartments.

7 The entrance survives until today, although a grand arch over the entrance had made way for modern lorries when this photograph was taken in the late 1970s.

8 Sales particulars and plan, family papers.

9 Readers were also lace machine makers and John Pollard jnr learnt his twisthand skills at a Reader machine while still at school. John

Pollard in conversation with Sheila Mason.

10 Note by John Pollard jnr.

11 Another complication was that "Anglo Scotian Lace" were tenants in Swiss Mills for a period.

12 Mains electricity gets its first mention in Anglo ledgers in 1921, with payments to the Derbyshire and Nottinghamshire Electric Power

Company and a note by John Pollard jnr tells us that at Swiss Mills the steam engine was scrapped in 1923.

13 In a letter to John Pollard jnr, when his father died.

The picture at top right is of Arthur Pollard and his wife Lillian at 42 Villa Street, "Chestnut Villa"

Click to read the next chapter

or -

Click here to go back to the top

|

|

Arthur Pollard, the Anglo Scotian Mills & Prosperity -

John Pollardís will set up a trust to manage the factory and to provide for his wife Eliza, who continued to live at Cromwell House. The firm then

operated under the name of "John Pollard Executors" until Eliza died in 1922. The trustees were Arthur Pollard, Samuel Weston1 a

lace yarn agent from Nottingham and Arthur Meakin the factory draughtsman. Arthur Pollardís agreement, for taking half of the profits, was renewed by the

trustees and at the age of 40 he was in effective charge of the factory. The period that followed, until the outbreak of World War I, saw the factory

Arthur Pollard, the Anglo Scotian Mills & Prosperity -

John Pollardís will set up a trust to manage the factory and to provide for his wife Eliza, who continued to live at Cromwell House. The firm then

operated under the name of "John Pollard Executors" until Eliza died in 1922. The trustees were Arthur Pollard, Samuel Weston1 a

lace yarn agent from Nottingham and Arthur Meakin the factory draughtsman. Arthur Pollardís agreement, for taking half of the profits, was renewed by the

trustees and at the age of 40 he was in effective charge of the factory. The period that followed, until the outbreak of World War I, saw the factory

prosper. The clock and bell, with its ornamental belfry, were moved around this time from the closed Silk Mill on High Road2. The belfry,

perched rather incongruously on the Swiss Mills roof, could be seen as a statement, a symbol of prosperity. In 1905-6, for example, sales of lace brought

in £37,6003 and profits of £6565. A new engine house was built in 1906 and three new lace machines arrived in that year. Also in 1906,

single story buildings, Earls Court and the Palace4, were erected along Villa Street, and most of the Pollardsí machines were moved there,separate

from those of the tenants. The date and initial "P" on the new engine house5 are shown left.

prosper. The clock and bell, with its ornamental belfry, were moved around this time from the closed Silk Mill on High Road2. The belfry,

perched rather incongruously on the Swiss Mills roof, could be seen as a statement, a symbol of prosperity. In 1905-6, for example, sales of lace brought

in £37,6003 and profits of £6565. A new engine house was built in 1906 and three new lace machines arrived in that year. Also in 1906,

single story buildings, Earls Court and the Palace4, were erected along Villa Street, and most of the Pollardsí machines were moved there,separate

from those of the tenants. The date and initial "P" on the new engine house5 are shown left.